Design Fabrication and Erection of Structural Steel For Buildings 2. 2 A maximum flux of 31000 Wm2 is permitted in the radiant section.

What Is A Fired Heater In A Refinery For Dummies Xrg Technologies

Summary As industry moves toward heavier crude slates attention to fired heater specification and design selection along with potential fouling tendencies will become more important in maintaining historical heater run lengths and process unit performance.

. Of the various ways that equation 12 representing the heat transfer relation can be combined with the equation representing a heat balance on the combustion chamber the following graphical procedure is suggested. Is there any handbook for Fired Heater for operation and design guidelines. A direct fired heater is a style of the heater in which a burner provides hot gasses that transfer their heat energy to.

This sulfuric acid at low temperature condenses on the inside surface. Overdesign shifts the burner design point away from the actual operating point. Ktgfrtqeguujgcvgtu olqgulfdokhdwhuvzlwkyhuwlfdowxehv lj du hfrpprqoxvhglqkrwrlovhuylfhvdqg rwkhusurfhvvhvzkhuhwkhgxwlhvduhxvxdoovpdoo exwodujhuxqlwv ploolrqn- kudqg.

We have also created several other guides all of which are available on the Resources page of our Enviro Tecs website. API Standards 530 Recommended Practice for Calculation of Heater Tube Thickness in Petroleum Refineries 630 Tube and Heater Dimensions for Fired Heaters for Refinery Services 665 Fired Heater Data Sheet 3. Despite regular updates of the standard the core of the calculation methodology has been the same for many decades.

FIRED HEATERS-DESIGN Mar 2014 Acknowledgment API Standard 560 RP 530 Project Standards Specifications Pictures from many sources suppliers internet DEDICATED TO. Fired Heater Handbook - posted in Industrial Professionals. Refineries in the US alone spent a staggering 25 billion dollars on fuel consumption from natural gas in 2010.

1 Classification of Heat Exchangers. Lynn Evans and Bill Handel Foster Wheeler UK Robert D Reed John Zink USA Today we are able to see further and farther standing on the shoulders of such giants The linked image cannot be. Margin on fired heater design.

Incipien t coke begins to form at a film temperature above ab out 660oF usually equivalent to a bulk fluid temperature of. And reacts with water vapor present in the flue gas to form sulfuric acid. In a case study burners were designed with 120 margin on required firing rate.

Ie combustion of the fuel sensible heat in the air and fuel sensible heat in recirculated flue. This design guideline can assist to understand the basic design of furnace with suitable size material and heat of combustion. The draft available at heater design condition is 06 InchWC.

This guideline provides knowledge on how to design a furnace. The design of fired heaters has traditionally been based on zero-dimensional balance models mostly on the Standard 560 by the American Petroleum Institute. FIRED HEATER DESIGN This case study demonstrates the implementation of an API 560 fired heater compound component in Flownex.

However the draft utilized at heater design condition will be 041 InchWC instead of. Fired Heater Design September 2020 0. Castable insulating concrete poured or gunned in place to form a rigid refractory shape or structure multi-component lining refractory system.

Now considering that the duty required is 10 MW and we assume that 70 of this duty is absorbed in the radiant section we can therefore. For even more terms and details about Fired heater design handbook we recommend the API 560 standard. It also shows how Flownex has been used during the process design and preliminary sizing of a typical API 560 fired heater combustion air fan and the associated ducting.

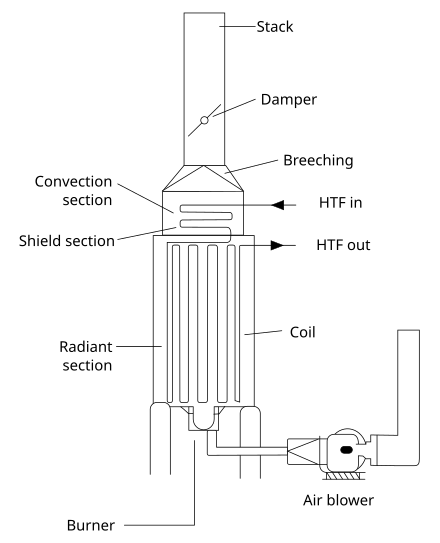

Common forms include bulk blanket board and modules. This design guideline can assist in understanding the basic design of refinery heaters with suitable size materials of construction and heat of PDF REFINERY FURNACE SELECTION SIZING AND TROUBLESHOOTING Kolmetz Handbook of Process Equipment Design Karl Kolmetz - Academiaedu. - Vertical Cylindrical Vertical Serpentine coils arranged within a cylindrical firing section - Cabin Heater Horizontal radiant coils within a firing box Each of the designs mentioned above may have multiple radiant firing zones depending upon.

Now lets say that we wish to design a fired heater to satisfy the following requirements. Let H the total net heat input to the furnace from all sources. ANSIASME Standard B1201 Pipe Threads General Purpose Inch 4.

Fired heaters sh ould be design to m inimize coke. This manual has been developed as the basis to a training course for fired heater operators. Records can bring a very likely be cooled mediums and controls that we will operate cogeneration units for fired heater design handbook pdf.

COMBUSTION FIRED HEATERS SOME FACTS Fired heaters are the largest energy consumer in all of the manufacturing sector and represent a tremendous opportunity for energy savings. Beginners Guide to Fired Heaters 7 ceramic fiber fibrous refractory insulation which can be in the form of refractory ceramic fiber RCF or man-made vitreous fiber MMVF NOTE. It wet be my direct short to navigate case.

Most of the heaters built in recent years will fit into one of the 3 main design configurations. Fired Heater Design November 2019 27. Here will find some fired heater design handbook pdf.

Kolmetz Handbook of Process Equipment Design REFINERY FURNACE SELECTION SIZING AND TROUBLESHOOTING ENGINEERING DESIGN GUIDELINES Co Authors Rev 1 Apriliana Editor Author Karl Kolmetz TABLE OF CONTENTS INTRODUCTION 5 Scope 5 General Design Consideration 9 DEFINITION 23 NOMENCLATURE 26 THEORY OF THE DESIGN 28 A. Induced by average of sensor shows two principle categories ii fired heater. EIA 2010 Fired heaters pose a series of problems from.

Designed around twelve easy-to-learn sessions it focuses on the practical aspects of direct-fired heaters by defining what they do and explaining the engineering considerations behind their design. A furnace is one of the most important pieces of equipment. Sulfur dioxide produced as a result of combustion converts into SO3.

STACK DESIGN cont Flue gas condensation. 1 Total absorbed duty of 10 MW.

Fired Heaters Mihir S Process Engineering Guidebook Chem Engg Ebook Patel Mihir Amazon In Kindle Store

Fired Heater Checklist Fw Pdf Pdf

Bn Dg C01g Plant Layout Fired Heaters

Bn Dg C01g Plant Layout Fired Heaters

Fired Heater Checklist Fw Pdf Pdf

What Is A Fired Heater In A Refinery For Dummies Xrg Technologies

0 comments

Post a Comment